Ground Support Training

We are able to provide the following type ground support training. Due to the fact that this is a total customized training we can only give you a roughly overview. Any training will be developed together with the customer. This must be happen because of the available airplanes, equipment’s and already existing experience.

Rigger Training Part 1

The qualification aim of the training is to qualify rigger to pack the parachute system (main and reserve canopy), to check the safety of used systems, to make a annual system safety check and to be able for basic rigging at the new system. The trainees should be qualified rigger with a minimum of one-year experience in rigging parachute systems.

The training includes:

- Packing main and reserve canopies.

- Chance of system configuration (opening device).

- Safety check with “go” or “no go” decision in case of any damages.

- Annual safety check.

- Basics about repair the system in case of damages.

Duration of entire training:

1 week (5 days a week)

Number of trainees:

Maximum 4 rigger

Rigger Training Part 2

The qualification aim of the training is to upgrade qualified rigger who passed Rigger Training Part 1 for maintenance and repair.

The training includes:

- Training canopy-patching.

- Training of single line replacement .

- Training of replacing complete line set.

- Training harness repair.

- Training container repair.

Duration of entire training:

1 week (5 days a week)

Number of trainees:

Maximum 4 rigger

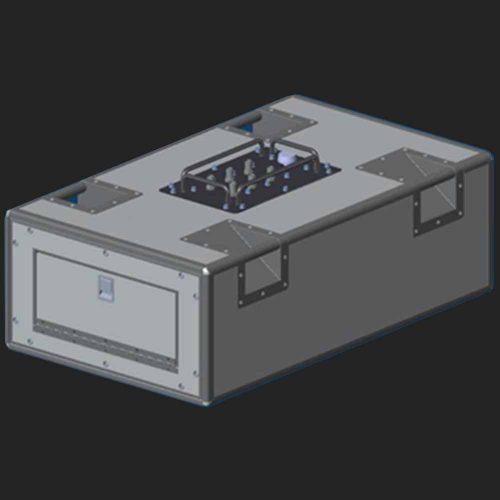

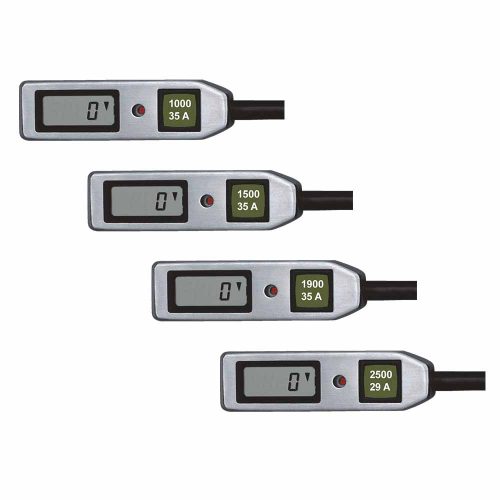

Oxygen Maintenance Training

The qualification aim of the course is to train the preselected oxygen crew into basic maintenance procedure to maintain the delivered oxygen system.

The training includes:

- General rules of conduct/training safety

- Introduction of products/equipment

- Oxygen fundamentals and the physics of gases

- Operational aspects how to handle oxygen/pressure/volume of gases

- Safety precautions in regard to handling of oxygen

- Restrictions and limitations include charts and data

- O2-Supply systems general date

- Oxygen ground support equipment

- System structure and operation

- Testing of equipment

- Post and pre flight checks

- Explanation/Demonstration “fault finding”

- System structure

- Test concepts

- Data and procedures

- Module component testing

- On the job training with fault finding in oxygen equipment

Duration of entire training:

1 week (5 days a week)

Number of trainees:

Maximum 3 per course